Case Study Part 2: Simulating Molds for Conformal Cooling Capabilities

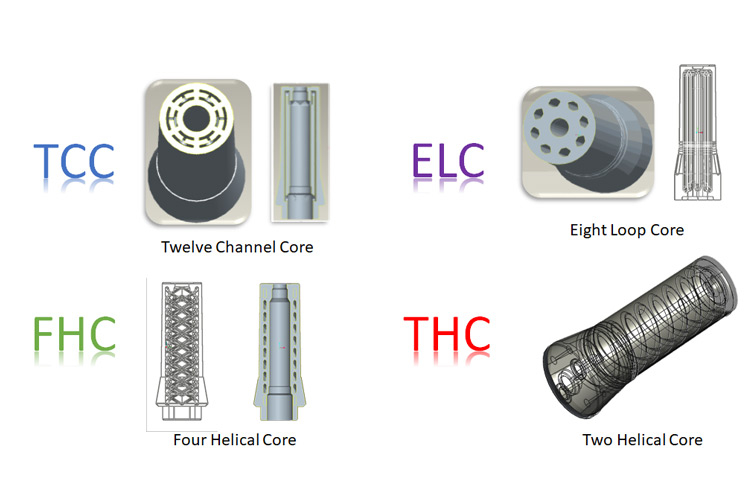

In Part 1 of this case study, a plastic parts manufacturer was looking to upgrade a traditional mold for pharmaceutical pill bottles. Part 1 highlighted how engineering calculations are used as part of the mold design process to quickly assess the capabilities of various design options. In that study, Anova Innovations compared four different cores to the core in the original mold.

The original mold ran with a simple bubbler. The objective of the new design was to improve the cooling capabilities of a core that goes into a production stack mold. All four new designs would require Additive Manufacturing (AM) technologies if a manufacturer wanted to produce them. AM provides the designer with more design flexibility than conventional machining, which can offer unrivaled cooling capabilities. Now that standard tool steels such as H13 are available with many AM methods, the use of 3D printed mold inserts is increasing. Mold designers will need to develop new design processes, including simulation, when incorporating 3D printed mold inserts.

To develop the right solution for this manufacturer, Anova Innovations used engineering calculations, mold filling simulation, finite element analysis (FEA), and computational fluid dynamics (CFD) to compare the four designs, decide on an approach, and refine the mold design.

To evaluate stress within the core, we used FEA. Anova also used CFD to evaluate the coolant’s pressure loss through the circuit and mold filling simulation to estimate the process conditions within the mold.

The Simulation Process

Comparing designs through simulation software is essential to ensure that the 3D-printed steel inserts will be reliable and capable of withstanding the demands of the injection molding process. 3D printing has allowed for a whole new range of unprecedented and untested design options that weren’t possible with subtractive manufacturing; the ability to simulate outcomes improves engineering decisions and reduces risks.

Therefore, when designers are simulating the performance of a mold, they will need to consider a range of data such as:

| • Fluid dynamics • Gas chemistries • Heat transfer/cooling potential • Melt pool characteristics • Microstructure |

• Porosity • Pressure • Process parameters • Residual stress • Temperature/temperature distribution |

The data collected during the simulation process can help to validate the quality of a mold, optimize the process, provide design modification ideas, and direct manufacturers toward the best mold option for their clients.

In Part 2 of this Case Study Series, we will discuss the importance of using mold filling simulations to estimate the process conditions within the mold so that the initial design concepts can be refined.

Filling Simulation

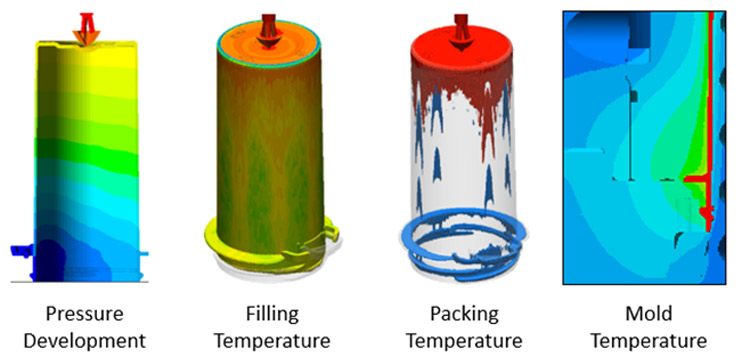

Mold filling simulation software can provide the designer with an understanding of the conditions that may develop within the mold cavity during the injection molding cycle under various conditions. Conditions of interest include pressure, time to cool, temperature, and part shrinkage.

Simulation allows for the evaluation of different scenarios. For example, an existing process can be evaluated using simulation, and the designer can look for opportunities for process refinement. A designer can also use mold filling simulation to evaluate the conditions that could develop within the mold under a normal process, as well as simulate a higher pressure situation that could occur based on the capabilities of the injection molding machine. The results from the latter can be used when considering the strength of the various design options and determining whether a particular design is capable. More discussion around that will be included in next month’s blog post.

Filling Simulation Results

Simulations were run to evaluate the conditions during filling, packing, and cooling of the mold under several scenarios. Results like these are used to set up the stress analysis and to refine the cooling channels within 3D printed steel cores.