Injection Mold

Statistically Capable Parts

Save money by decreasing cycle time

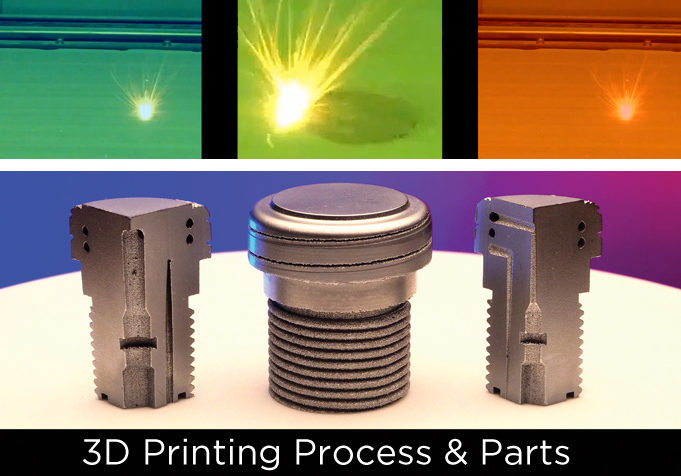

Our Process:

-

Comprehensive Mold Design and Build:

Our team of experienced designers & engineers works with you to understand your specific requirements and create customized mold designs with both Conformal/Additive Tooling and Traditionally Cooled Tooling.

-

Moldex3D Simulation:

We run rigorous simulations using Moldex3D to test and prove the value of Conformal/Additive tooling, ensuring that we manufacture molds that are both highly efficient and cost-effective.

-

Unit Mold Testing:

If the simulation proves value for Conformal/Additive Tooling, we build 2 single cavity-unit molds, one using Conformal/Additive Tooling and the other using Traditional Cooled Tooling to test this value in the physical world of molding.

-

Design and Build Production Mold:

If the unit mold tests further prove value, we design and build the production mold.

-

Biodegradable Resins:

We can work with you to pair our innovative mold designs with biodegradable resins. Most of these resins tend to cycle longer which takes advantage of the improved cooling.

Culture

Our team’s reputation is an intangible, invaluable asset that provides Anova with a sustainable competitive advantage in the marketplace. Delivering outstanding customer service requires a culture and a mindset that emphasizes achievement, impeccable service, and problem-solving through focused ideas and inventiveness.

- Relentless continuous improvement both internally and externally

- Meet our goals while maintaining positive partnerships with our customers, coworkers, and suppliers

- Show appreciation to all in the process

- Innovative technology and systems

- Satisfaction in work

- Candid, honest, open communication

- Data-driven decision making

- Proactive thinking: begin with the end in mind

- Work as a team while pushing yourself to become self-reliant

- Ability to mentor and “teach” and also enjoy being a “student” of the more experienced on the staff while educating and mentoring apprentices

The Apprenticeship Vision is a program that helps students in a disadvantaged school district start a technological career out of high school.