Simulation and Mold Engineering

Injection Molding Simulation Services

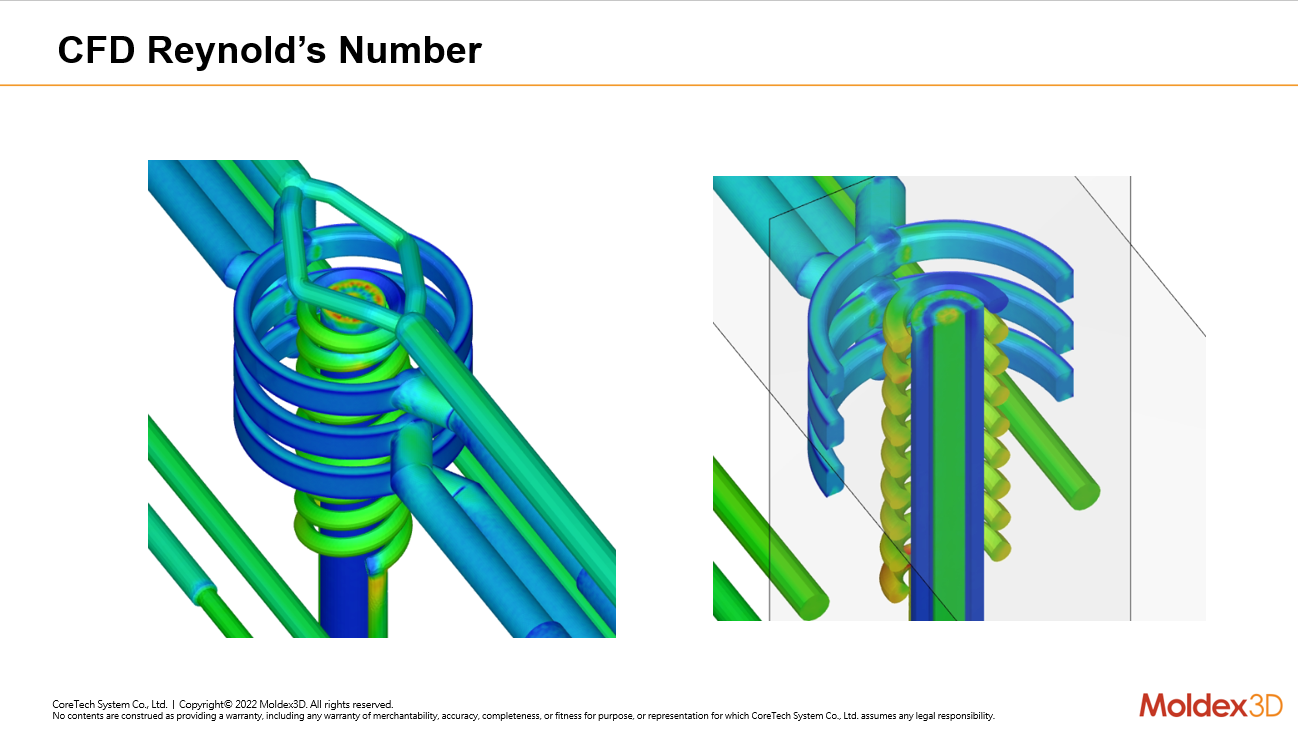

Anova Innovations is an industry-leading solutions provider for the injection molding industry. By applying advanced engineering principles in mold design and pioneering the strategic use of additive manufacturing, we’ve helped clients reduce cycle times, produce higher-quality parts, and boost productivity. Through our injection mold simulation services, we can help you overcome traditional boundaries and propose innovative solutions previously unimaginable in the industry.

Learn more about our Simulation Services

Anova Innovations provides best-in-class computer-aided engineering (CAE) molding simulation services to manufacturers in the injection molding sector. This service ensures that a part fills properly, accelerates the process from concept to completion, and minimizes expensive rework. If your engineers need to visualize every element of the part as well as its performance, Anova is here to help.

[Reach out Today to Learn More]

Flow, Pack, Cool, Warp

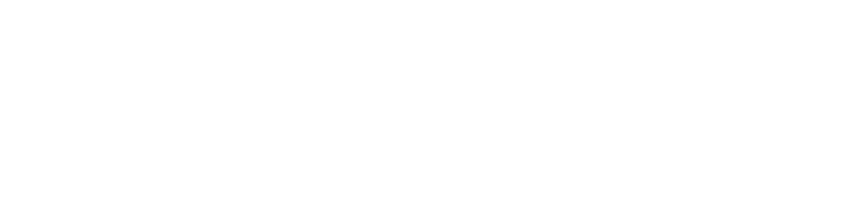

Computational Fluid Dynamics (CFD)

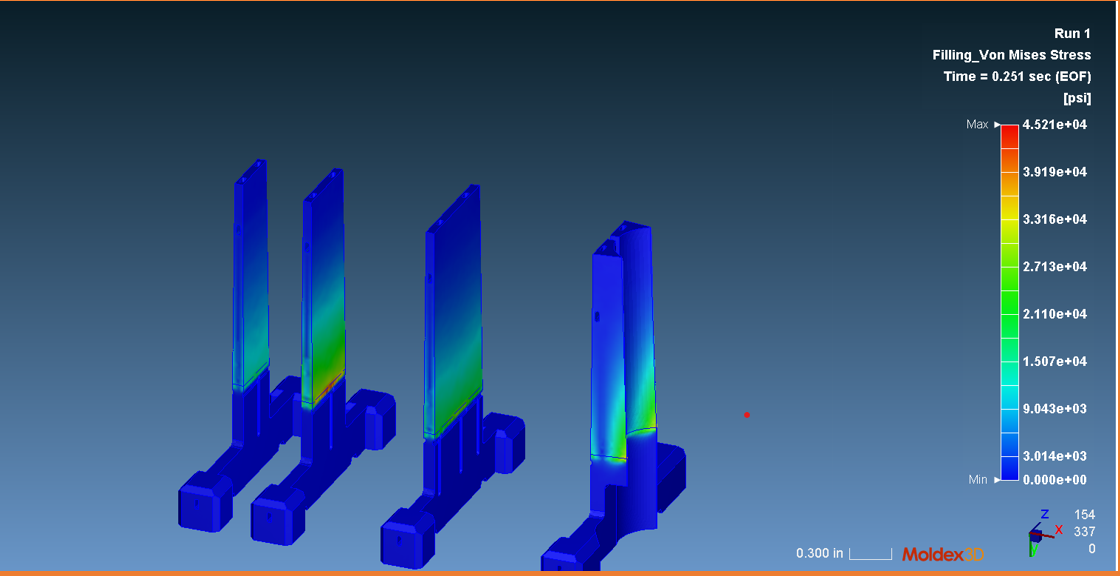

Stress Analysis

Seasoned Simulation Analysts

When it comes to injection molding simulation, you need an experienced team of analysts to interpret results. With a proven team, you can avoid misreading critical data and manufacturing a part that fails to meet your specifications. From part design and prototyping to material chemistry and tool building, Anova’s analysts have decades of experience in all aspects of the injection molding process.

But Anova has more than the team. We have the right tools for the job.

Anova leverages the power of Moldex3D, the world-leading plastic injection molding CAE software. With unrivaled analysis technology, Moldex3D helps carry out in-depth simulations for a multitude of molding processes and optimizes product design and manufacturability. With its compatibility and adaptability, manufacturers can streamline the connection between Moldex3D and almost any mainstream computer-aided design (CAD) system.

More than a Report

Anova does more than send you a report. We provide one-of-a-kind consulting, part review, and support to guide your engineering team toward making the best product possible.

Unlock new cost-saving opportunities, discover the benefits of shortening your time-to-market (TTM), and optimize your entire manufacturing process.

Core Shift

Analyze, investigate, & breakdown potential core shift. Anova will determine if it Is due to the melt delivery system, molding process, and/or the mold.

Industries We Serve

Anova is known in the injection molding industry as the go-to solutions provider for the medical, packaging and pharmaceutical markets.

When you’re ready, reach out today by filling out the form below or visiting our contact page.