Design/Build Molds

Anova specializes in overcoming significant challenges in development, mold design, and production in injection moldings. This includes troubleshooting for unforeseen challenges like molding defects, shrink & warp issues, and/or dimensional challenges while revealing hidden potential such as cycle time. This front end work shortens development times and minimizes risks.

Need help finding ideal production parameters to realize the desired part quality and productivity, or looking to minimize core shift, Anova wants to help.

Anova Innovations, with its use of proprietary and commercial developed software, will guarantee the cycle time in an agreed-upon molding machine, including a discount off mold purchase price.

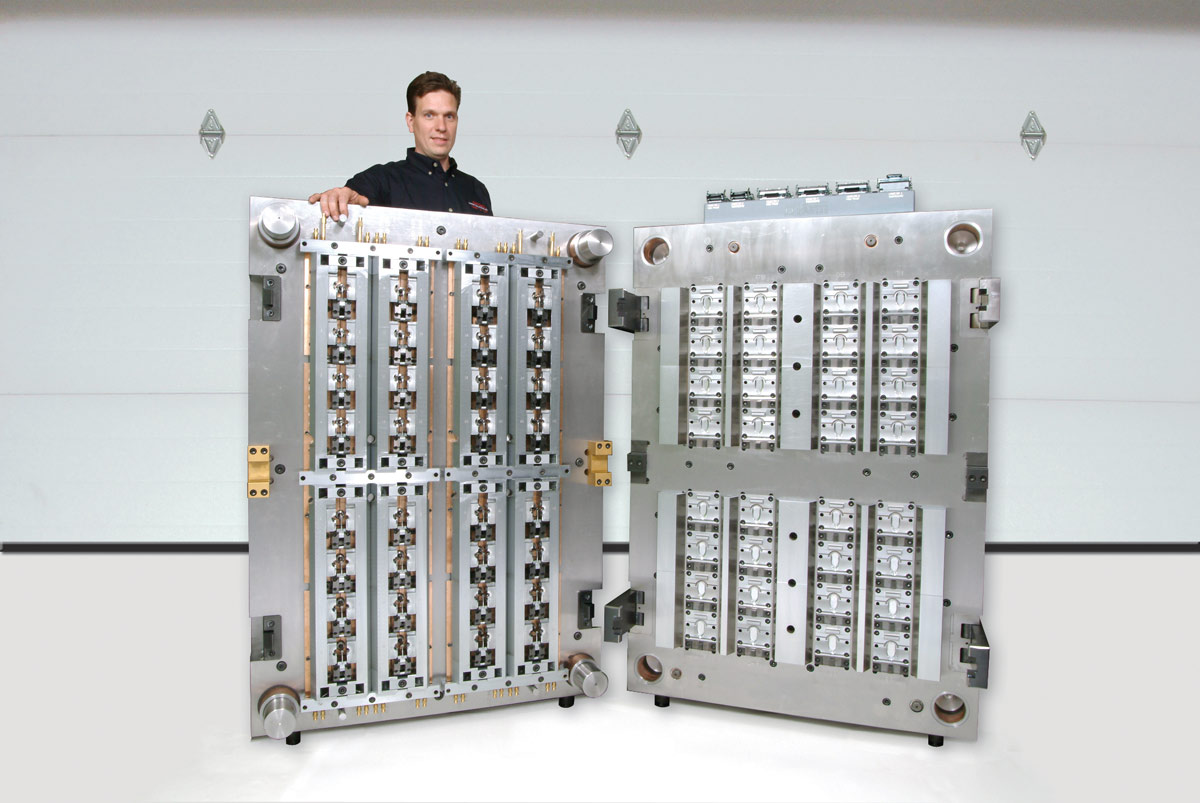

Mold Design

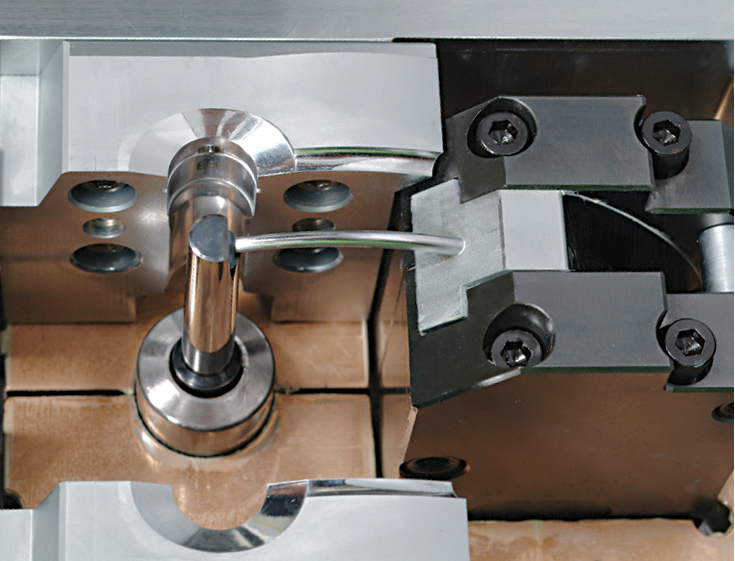

- Complex Geometry

- Molds up to 144 cavities cycling under 5 seconds

- Complex Motions, including core pulls at arcs & angles

- Unscrewing Molds

- Collapsing Cores

- Molds with Multiple Slides and/or Lifters

- Delays and Accelerators

- In Mold Close

- Compression

We stand behind our work!

Need a custom job done?

Contact us an let us bring your vision to reality.

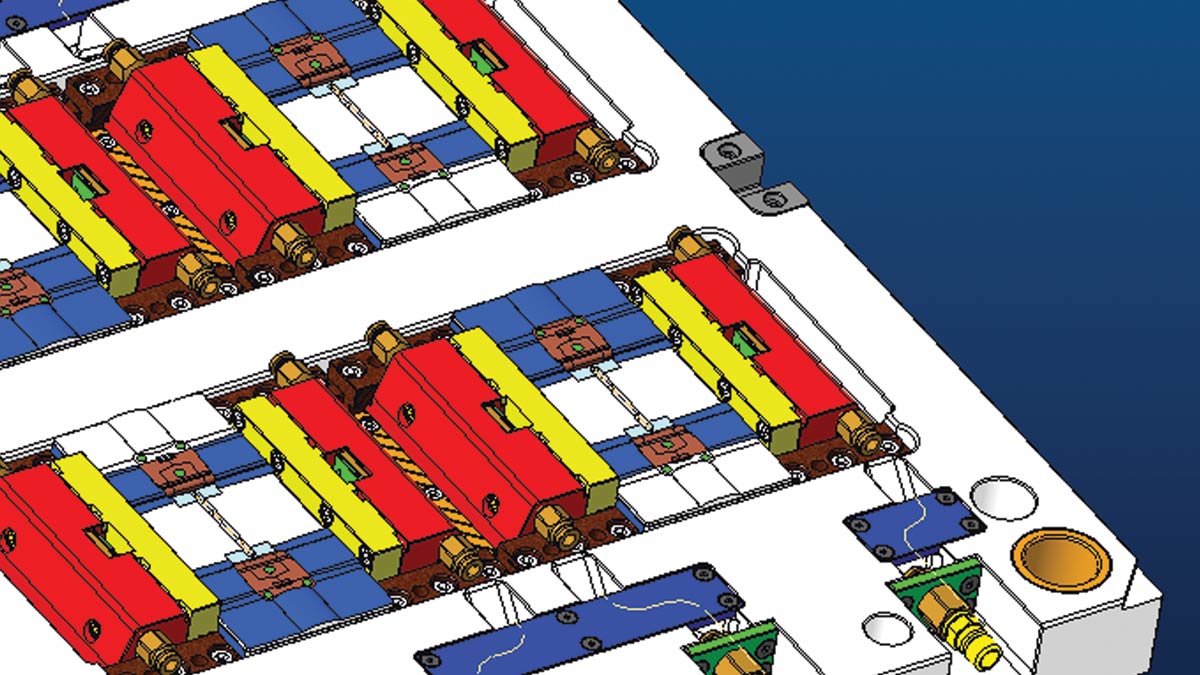

Anova's Process of Mold Design

Anova Innovations' designers have designed injection molds that are used throughout the world in the medical, packaging, and pharmaceutical industries.

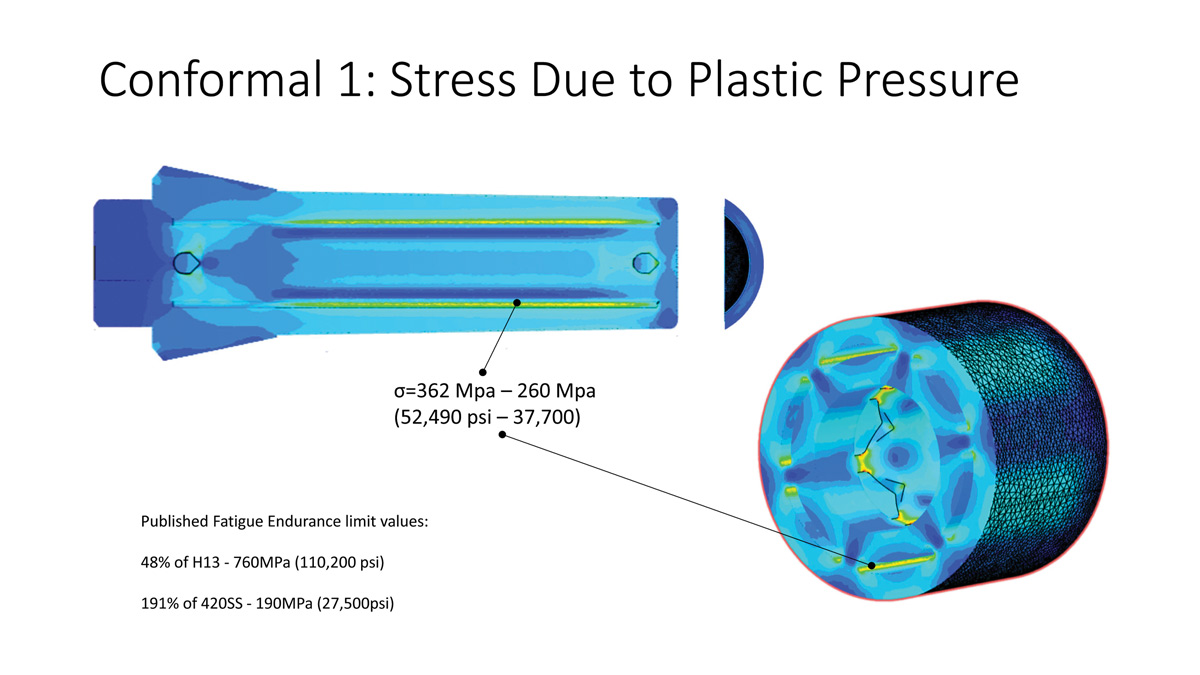

Mold Engineering to help predict, minimize & eliminate

- Molding Defects

- Fill Analysis

- Shrink & Warp

- Core Shift

- Cycle time estimating