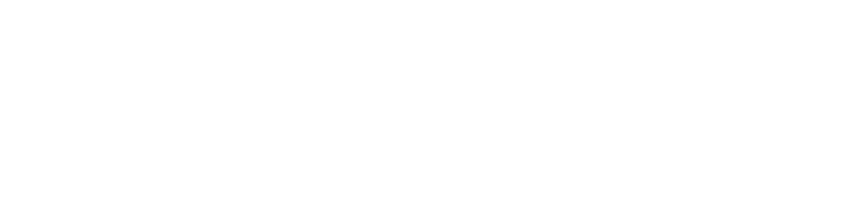

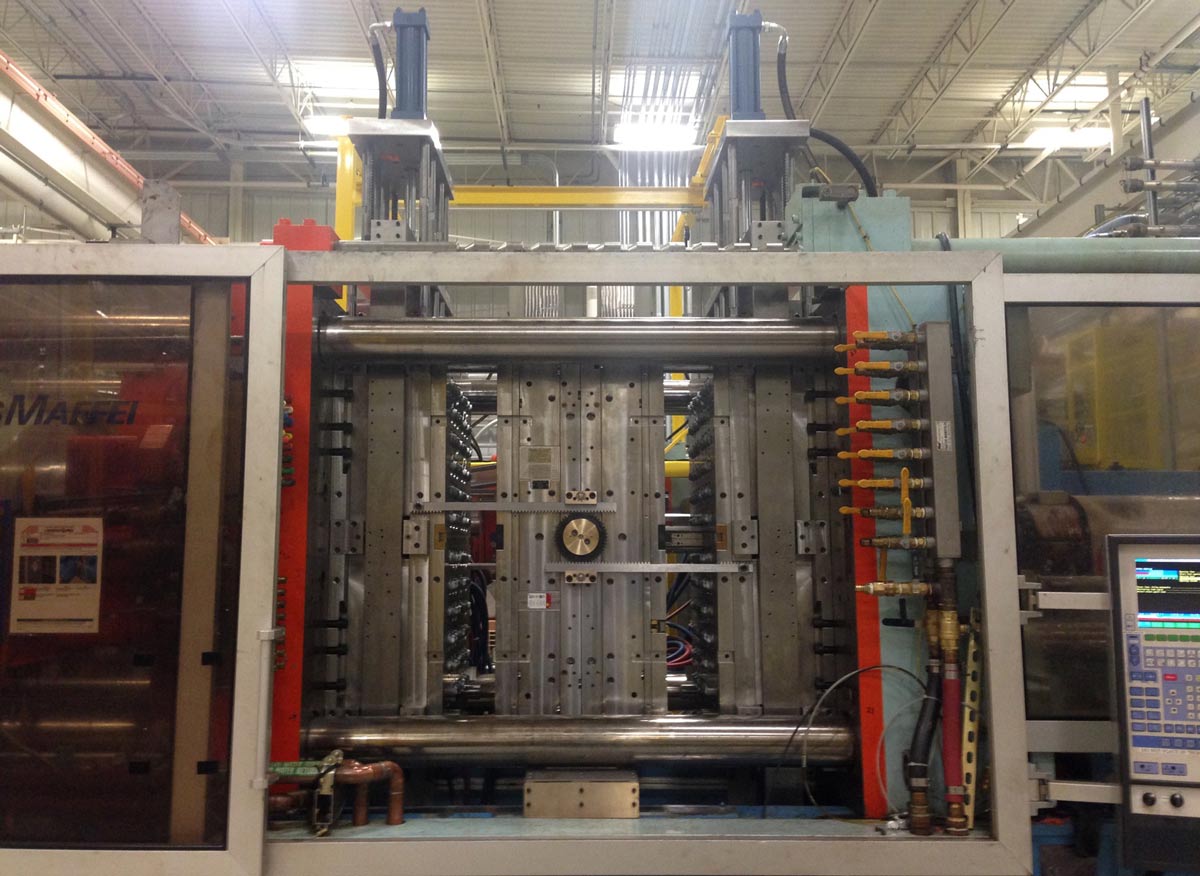

Mold Insert/Component Build

Mold Insert Build/Reverse Engineering

Reverse engineering is "the reproduction of a manufacturer's product following detailed examination of its construction or composition."

CAD data lost or damaged, vendor will not supply the data, and/or changes made to the tooling are not accurately represented in the data?

Let Anova help, we provide mold reverse engineering to recreate molds when the original design files or CAD models don’t exist, and/or are not accurate.

Quality Policy

We provide relentless, continuous Improvement both internally and externally to meet our goals. We will exceed our customers' requirements and expectations while maintaining positive partnerships and relationships with our customers, coworkers, and suppliers

- 100% Documentation:

- Critical dimensions

- Product print dimensions

- Shut-off surfaces, Rotating fits, Sliding fits

- Gate Diameters

- Successful projects are not just about inspecting the numbers, but inspection and monitoring for the root cause. Often the root cause of a dimensional issue may not be a dimensional issue, it could be due to poor gate location, cooling system design, and/or attributes like polish, broken edges, improper draft, etc. This is why mold designers & mold makers run our inspection equipment

Project Management

- Weekly project reporting (Gantt)

- Customer-specific Program Manager

- Anova Liaison to support molds in your facility

- Troubleshooting and problem solving

- Direct relationship with plant personnel

- Industry knowledge and expertise

Need a custom job done?

Contact us an let us bring your vision to reality.

Reproducing the Original Mold

Whatever the reason may be to reverse engineer the mold and/or product. Anova has the experience and the knowledge to get the job done. Our team's stellar reputation gives our company a competitive edge in the marketplace. Every employee comes together as a team to be sure the product is of the highest quality and works as expected. Using data-driven decision-making and proactive thinking, our eye is always on the end result -- to ensure word class tooling.