3D Metal Printing: The Sustainable Manufacturing Solution Companies Need

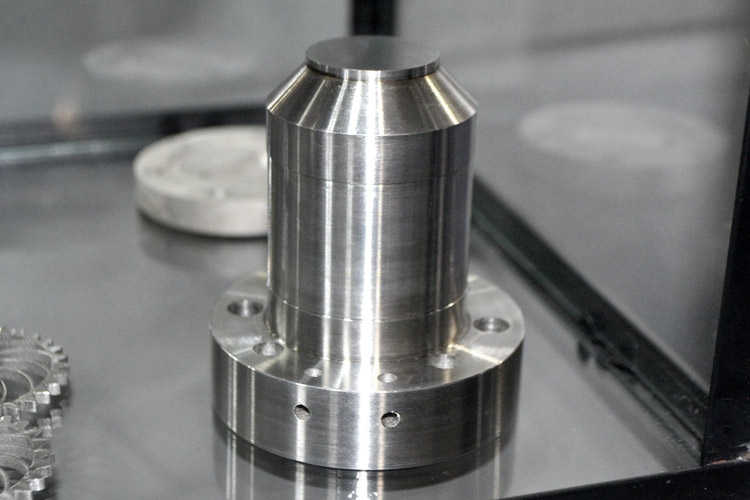

3D metal printing, also known as additive manufacturing (AM), is radically changing the manufacturing sector. Not only is it unlocking new levels of productivity, affordability, and agility, but it may also be the key to long-term sustainability.

If you’re looking for a solution that can help maximize your bottom line while minimizing your carbon footprint, AM might just be it. In this piece, Anova Innovations, an emerging leader in 3D metal printing, discusses the latest AM market trends, companies that have adopted AM technology, and the ways in which 3D printing is more sustainable than traditional manufacturing.

The Booming Additive Manufacturing/3D Metal Printing Market

Outside of global tourism and travel, there are few industries that are growing as fast as AM. In fact, the global AM market size in terms of revenue was valued at over $11 billion in 2021. Today, analysts expected it to reach nearly $35 billion by the end of 2028, which means they expect it to grow at a compound annual growth rate (CAGR) of roughly 20.50 percent between 2022 to 2028.

AM’s growth has many different drivers, with market leaders in aerospace & defense, automotive, and healthcare really putting the pedal to the metal. However, other industries such as chemical, consumer goods, and energy are also major contributors. A few of the companies that are testing out this cutting-edge Industry 4.0 technology include:

- Airbus (aerospace)

- BASF (chemical)

- Equinor (energy)

- L’Oréal (consumer goods)

- Medtronic (healthcare)

- Volkswagen Group (automotive)

From prototyping to on-demand printing, companies are leveraging the power of AM to shorten production times and boost profits. But there is also another benefit: it’s sustainable.

3D Printing as a Sustainable Manufacturing Solution

The global production sector is responsible for one-fifth of carbon emissions and consumes 54 percent of the world’s energy sources. However, thousands of companies are now taking science-backed steps to reduce emissions. One of the methods they’re using is AM.

Because the type of alloy a manufacturer uses and part geometry highly impact emissions, traditional manufacturing is sometimes the more sustainable option. However, the sustainability of AM goes beyond production.

In fact, the benefits start with sourcing. Because of the near-net-shape aspect of AM, which minimizes raw material utilization and finishing operations, companies can reduce their material needs. Moreover, with a reduced need for machining, AM can often reduce their energy usage.

In traditional manufacturing, manufacturers also have to contend with an energy-intensive supply chain, often shipping materials and products to faraway sites. Conversely, AM creates more opportunities for cloud manufacturing, also known as distributed manufacturing and local manufacturing. With cloud manufacturing, businesses can produce tooling and products right where they are. The ability to locally produce items dramatically decreases a business’s carbon footprint.

In many sectors, such as aerospace & defense, distribution, and transportation, reducing part weight could save thousands of pounds of fuel. AM allows manufacturers to create products that combine the function of multiple parts and use lightweight alloys.

AM also makes conformal cooling possible. Conformal cooling is the process of using conformal cooling channels (CCCs) in plastic injection mold tools. CCCs follow the geometry and contours of a mold and provide uniform cooling. Manufacturers’ improved ability to cool molds through conformal cooling channels reduces cycle times (energy usage), improves part quality (waste), and opens up new options for manufacturers to use bioplastics.

The new ability for on-demand printing also has the potential to reduce emissions. By minimizing the need for storage and transportation of feedstock, companies may be able to improve the bottom line and enhance their sustainability efforts during the manufacturing and distribution phases of the product life cycle.

Finally, AM not only uses less material during production, but the process is better suited to use recycled and reclaimed materials. Once again, this perk is not only good for the environment, but it’s good for companies’ pocketbooks as well.

A More Sustainable Future Starts Now

From start to finish, AM’s potential for increased sustainability can be seen all the way down the value chain. Additionally, it does more than help manufacturers reduce their emissions; it also helps end-users reduce their carbon footprint.

For example, the weight of an aircraft correlates directly with fuel efficiency and, therefore, emissions. In fact, experts at Honeywell estimate that every pound of an aircraft eats up about $10,000 in annual fuel costs. That also means that several thousand gallons of fuel are being used due to unnecessarily heavy parts. Put simply: If the parts of the plane are lighter, then the plane will use less fuel.

Find Out More

Anova Innovations is an industry-leading solutions provider for the injection molding industry. By applying advanced engineering principles in mold design and leveraging the power of AM, we are helping companies revolutionize the way they make products.

If you’re interested in how 3D metal printing could help you increase productivity, improve profits, and reduce waste, reach out to Anova Innovations today.