18 Essential Additive Manufacturing Terms You Need to Know

From binder jetting and directed energy deposition to photopolymerization and powder bed fusion, the jargon around additive manufacturing can be challenging to keep straight. To help alleviate some of the confusion, Anova Innovations breaks down some of the most essential industry terms. For manufacturing veterans, this piece can be a useful refresher. For the newcomers, it can serve as a road map to better understanding your industry.

1. What is Additive Manufacturing?

Additive manufacturing (AM) is a broad term for any process in which a person or machine creates a part by adding, depositing, and/or layering material. These layers of material are typically metal, plastic, or steel. Nearly every step of the additive manufacturing process is computer-aided in order to produce highly intricate shapes. Common AM processes include:

- Binder jetting

- Directed energy deposition

- Material extrusion

- Material jetting

- Sheet lamination

- Vat polymerization

2. What is Binder Jetting?

Binder jetting, or binder jet 3D printing, is an additive manufacturing (AM) process in which an industrial printhead selectively deposits a liquid adhesive binder onto a substrate (a thin layer of powder particles) to build an object. This process occurs one layer at a time. Manufacturers commonly use ceramic, metal, or sand during the AM process to create full-color prototypes, large cores and molds, and parts.

While similar to material jetting, where a 3D printer deposits droplets of build material and sinters the part for final density, binder jetting uses a binder to forge a material bond. Among manufacturers, binder jetting is often considered one of the fastest, if not the fastest, AM process.

3. What is Build Material?

Build material is the material that a 3D printing machine uses to manufacture a 3D object. Common build materials include but are not limited to:

- Carbon Fiber

- Graphite

- Metal

- Paper

- Plastic

- Thermoplastics

These materials help determine a product’s texture, strength, and rigidity.

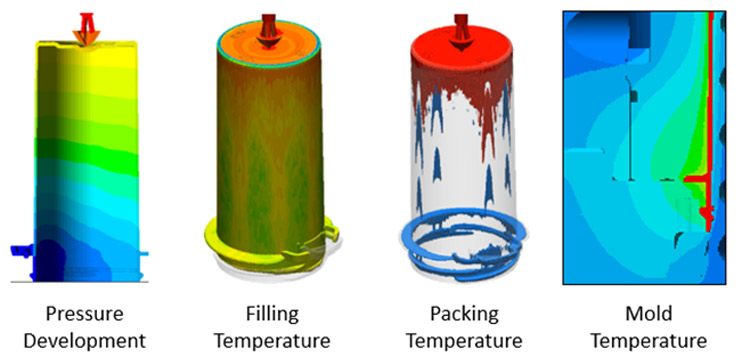

4. What is Conformal Cooling?

Conformal cooling is a process that uses conformal cooling channels (CCCs) to provide faster and more uniform cooling in a part. It allows part manufacturers to:

- Reduce cycle times

- Produce higher-quality parts

- Boost productivity

- Enable the use of bioplastics

5. What are Conformal Cooling Channels (CCCs)?

Conformal Cooling Channels (CCCs) follow the geometry and contours of a mold to provide uniform cooling. They’re built into a mold through additive manufacturing. CCCs stand in contrast with traditional straight-line cooling channels that are milled or drilled into a mold. Because straight-line cooling channels don’t follow the contour of a part, they have lower cooling efficiency for complex parts. Through a mold with CCCs, part manufacturers reduce warpage, increase productivity, and produce higher-quality products.

6. What is Directed Energy Deposition (DED)?

Directed enginery deposition, also known as laser-engineered net shaping and directed light fabrication, is an additive manufacturing (AM) process. During this process, a machine uses focused thermal energy via laser, electron beam, or plasma arc to fuse metal powder or wire material together to form a part.

DED systems differ from powder bed fusion (PBF) systems in various ways. For instance, DED systems do not require a powder bed. For that reason, DED systems can do repairs and print on existing parts. Moreover, unlike PBF systems, DED systems use larger metal powder sizes that require higher energy density. While this does increase build rates, it also creates a poorer surface quality.

7. What is a Mold Cavity/Core?

A mold (tool) has two sides: a cavity and a core. Together, they make the shape of a part. The cavity (A-side) is the void inside the mold where the injection mold machine injects molten material, typically plastic. The cavity is also where a part gets its shape.

The core (B-Side) is typically the interior side of the part. It’s also the side of the mold with the ejection mechanism. After the plastic cools, the injection molding machine pulls the two sides apart to eject the finished part.

8. What is a Feedstock?

In the context of additive manufacturing (AM), a feedstock is a machine’s source of build and binder-material powder. This powder is released from a printhead/nozzle to build a 3D object.

9. What is Injection Molding (Moulding)?

Injection molding is a process manufacturers use to produce high-volume parts. The process requires three main components: an injection press, a mold, and a clamp. The injection press, also known as an injection molding machine, injects molten materials (thermoplastic, glass, metal, plastic, etc.) into a mold. The mold clamp ensures the machined part (mold) doesn’t move during the process.

Once in the mold cavity, the material cools and hardens, and the part is complete. The primary advantage of injection molding is the ability to scale up production expeditiously.

10. What is Material Jetting (MJT)?

Material jetting (MJT) is one of many additive manufacturing processes. With MJT, an industrial printhead selectively deposits build material such as plastic, metal, or sand. With metal, material is jetted onto a build tray using a continuous jetting or drop-on-demand (DOD) process until, layer by layer, a cross-section of the part is complete. This resulting cross-section then needs to be sintered to achieve final part density.

The most significant benefits of MJT over other additive manufacturing processes are its speed and volumetric output. However, there are a few downsides to MJT as well, such as part shrinkage and limited wall thicknesses.

11. What is Modeling?

Modeling, short for computer-aided design (CAD) modeling or three-dimensional (3D) modeling, is the process of visualizing, testing, and refining a part digitally before production. Manufacturers in the additive manufacturing sector will model objects in cross-sections, or “slices,” using CAD software, such as PTC Creo-(Pro/ENGINEER). When they’re ready for production, they’ll use a stereolithography (STL) or additive manufacturing (AMF) file to 3D print the part.

12. What is Powder Bed Fusion (PBF)?

Powder bed fusion (PBF) is one of many additive manufacturing (AM) processes. In this process, a laser or electron beam selectively fuses powdered material layer by layer on a powder bed. PBF is made possible by selective laser sintering (SLS) technology, in which a laser partially melts particles and fuses them together.

PBF allows manufacturers to produce high-value products not technically feasible through traditional subtractive manufacturing processes. Further, it enables parts with exceptionally complex geometrics to retain strength. However, PBF is significantly more expensive and slower than other AM processes, such as directed energy deposition (DED) or binder jetting.

13. What is Prototype Tooling?

Prototype tooling, also known as soft tooling or rapid tooling, is one of the most critical steps in product development. During this phase, engineers demonstrate how a new design will perform and identify necessary changes before production starts. They may begin this process with a simulation and then move on to create an actual prototype mold.

Prototype tooling follows many of the same steps production molding does. However, the output is much smaller and is primarily used to identify functional issues.

14. What is Production Tooling?

Production tooling, or just tooling, is the physical mass production of a product. Manufacturers will use a mold and inject the cavity and core with molten material, likely plastic. As it cools, this material takes the shape of a tool. Finally, the part is ejected from the mold.

15. What is Rapid Prototyping?

Rapid prototyping (RP) is the process of expeditiously creating a physical part directly from a computer-aided design (CAD) model. Rapid prototyping can occur through a variety of manufacturing techniques, most notably 3D printing. Manufacturers do this to analyze and evaluate a part or specific features of a part.

16. What is a Reynolds Number?

Mold engineers use a Reynolds number to characterize a flow pattern. When the number is low, the flow tends to be laminar or streamlined. When the number is high, the flow is turbulent. When simulating molds, engineers typically have a target Reynolds number to evaluate its cooling efficiency.

In injection molds with conformal cooling channels (CCCs), mold manufacturers want a turbulent flow, rather than a laminar flow, for its superior ability to transfer heat.

17. What is Selective Laser Sintering (SLS)?

Selective laser sintering (SLS), in the context of 3D metal printing, is an additive manufacturing (AM) technique that uses a high-power laser to sinter build-material powder into a solid structure. This process occurs because of solid-state diffusion, where materials merge on an atomic level.

In essence, a laser welds the cross-section of a part one layer at a time. Through this process, manufacturers can build a prototype that has an almost identical density as the raw material, such as aluminum, stainless steel, or titanium. Most parts will require a post-sintering heat treatment to increase surface hardness and close pores.

18. What is Subtractive Manufacturing?

Subtractive manufacturing is the process of creating a part by removing layers of material (metal, plastic, or steel). Subtractive manufacturing requires computer numerical control (CNC) or electrical discharge machining (EDM) machines.

Subtractive manufacturing can produce a considerable amount of waste. Therefore, manufacturers now use it more for prototyping and producing low-volume parts and expensive components. Common types of subtractive manufacturing include:

- CNC machining (boring, drilling, milling, turning, etc.)

- Electrical discharge machining (EDM)

- Laser cutting

- Water jet cutting

19. What is Vat Photopolymerization?

Vat Photopolymerization is a type of additive manufacturing (AM) technology. Using a vat of liquid photopolymer resin and an ultraviolet (UV) light, it produces 3D objects by constructing them with layers of cured resin. There are three types of vat photopolymerization, which include:

- Stereolithography (SLA)

- Digital Light Processing (DLP)

- Continuous Digital Light Processing (CDLP)

Fun fact: Stereolithography was the first AM process to be patented and commercialized.

Innovate with Anova

Whether in the prototyping or production stage, there is a lot to keep straight when it comes to additive manufacturing lingo. Further, finding a solution for a specific part can be challenging.

If you’re looking for 3D steel printing solutions that will minimize downtime and maximize production, you should contact Anova innovations. We specialize in applying advanced engineering principles in mold design and pioneering the strategic use of additive manufacturing. Our methods enable our clients to overcome traditional boundaries and propose innovative solutions that add value to your business. If you’re interested in learning more, reach out today.