Posts by Jim Piersol

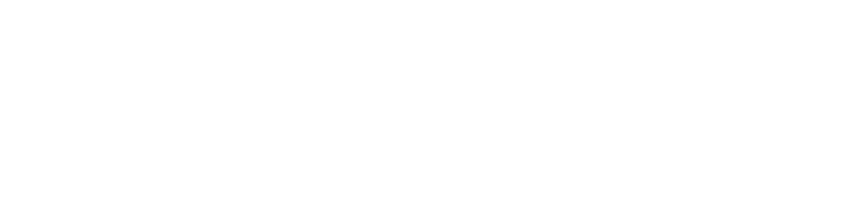

Case Study Part 4: Heat Energy Removal/Time to Cool

Heat Energy Removal/Time to Cool Thus far, for the Vial Case Study, we have reviewed the Core Designs, Simulation, & Stress. Next is Heat Energy Removal & Time to Cool During the injection molding process, heat energy is removed from the molten plastic in several ways: Conduction: The mold, typically made of metal, acts as…

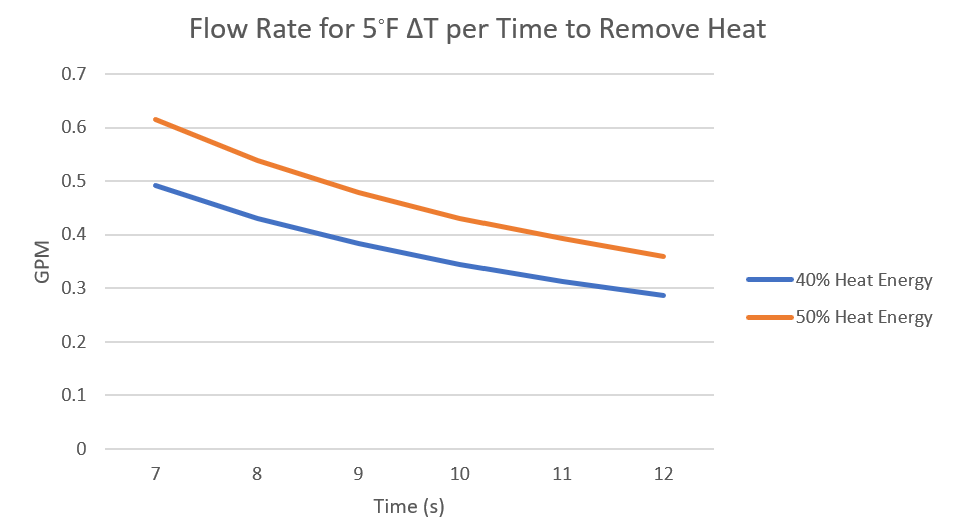

Read MoreCase Study Part 3: Stress Analysis

The next step of the design process is to analyze the amount of stress that may develop within each of the prospective mold core inserts based on the results of the injection molding process simulation. This step is incredibly important because the plastic pressure within the mold cavity can be very high, and the placement…

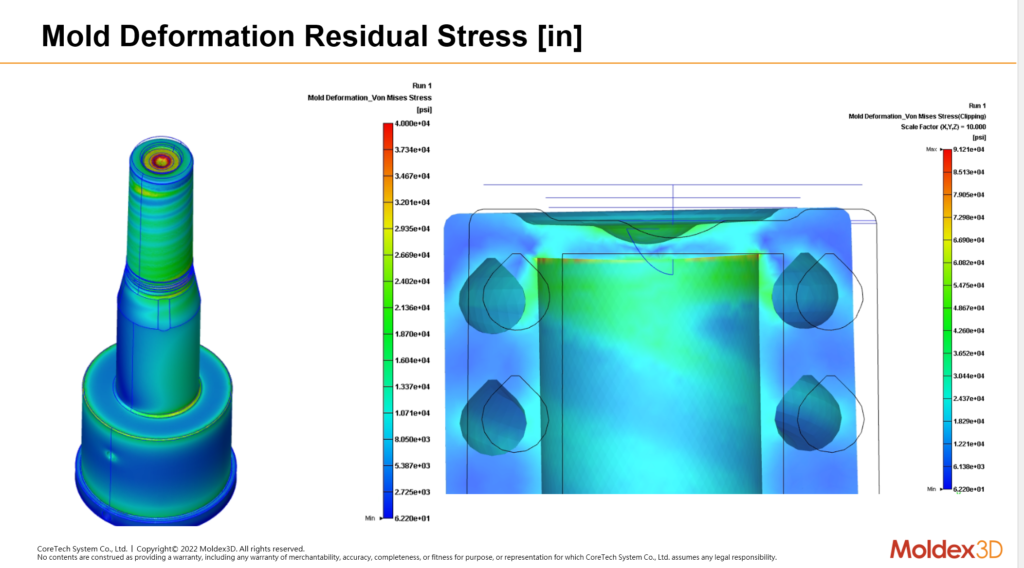

Read MoreMoldex3D & Anova Innovations: Forging New Partnerships for your Future Workforce

The manufacturing industry has around 500,000 open job positions, and manufacturers all over the country are struggling to fill those spots. Even with compensation that is almost double that of federal minimum wage, these job positions remain vacant. With its unique internship/apprenticeship program, Anova Innovations, in partnership with Erie High School, is working towards alleviating…

Read More